With the growing push in direction of sustainability and effectivity, the electrification of business automobiles isn’t just a technological milestone however a necessity. As electrical automobiles (EVs) revolutionize transportation and prolong their attain into numerous industrial sectors, the demand for sturdy and dependable battery techniques turns into ever extra essential.

Revolutionizing Industrial Battery Expertise

Industrial batteries, notably these utilized in EVs, are topic to excessive situations and rigorous calls for. These batteries should keep optimum efficiency over prolonged durations, typically in environments the place situations might be extreme. The effectivity of a battery is considerably hampered if it can not successfully handle the warmth generated throughout operation. Poor thermal administration can result in decreased efficiency, security hazards like thermal runaway and an in the end decreased lifespan.

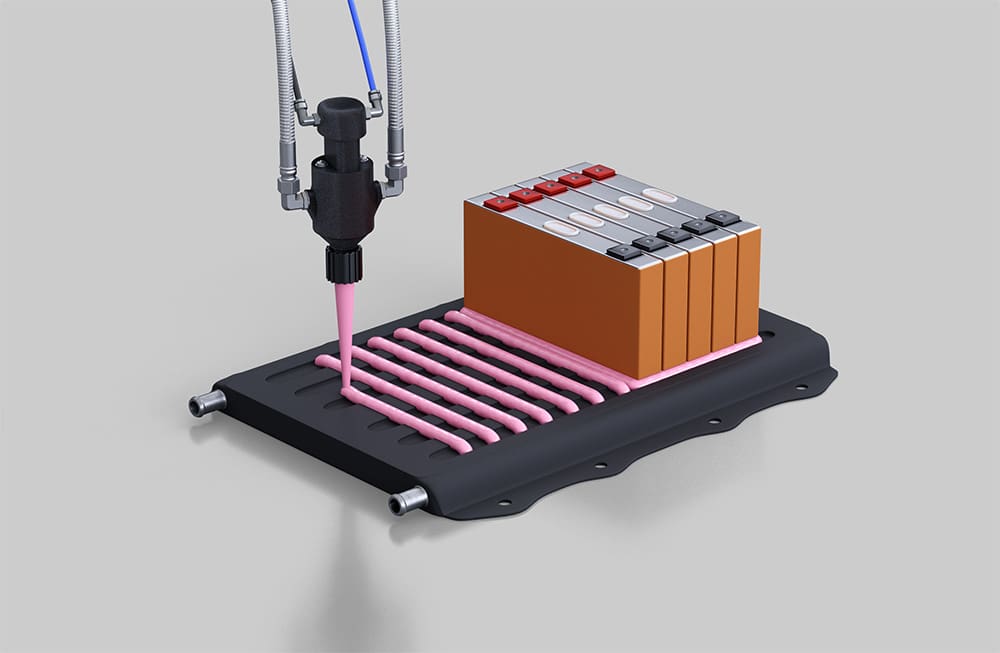

Furthermore, EV batteries must display outstanding sturdiness and reliability to face up to the mechanical stresses and vibrations inherent in industrial functions. That is the place thermally conductive structural adhesives play a essential position, guaranteeing the battery parts stay securely bonded whereas facilitating efficient warmth dissipation.

Thermal Administration and Sturdiness

Poor thermal administration in batteries can result in decreased efficiency and security hazards. Parker’s CoolTherm® TC-2002, a two-component adhesive system, is engineered for superior thermal conductivity. It enhances warmth dissipation, reduces overheating dangers and promotes battery longevity. The structural adhesive’s sturdy mechanical bonding maintains structural integrity, very important for industrial functions the place batteries are topic to fixed movement and vibration. Moreover, properties like flame retardancy and electrical isolation make CoolTherm TC-2002 an optimum answer for security and efficiency reliability.

Actual-World Industrial Functions

In real-world situations, Parker’s CoolTherm thermal administration supplies have been instrumental in enhancing the efficiency and reliability of EV batteries utilized in sectors resembling building, mining, agriculture and logistics. An electrical forklift producer integrating CoolTherm TC-2002 into their battery design, for instance, will obtain improved warmth administration and structural help. This integration not solely prolonged the battery life but in addition contributes to the forklift’s total vitality effectivity and operational security.

Rising Markets Fueling Superior Battery Demand

Past conventional automotive functions, a number of rising non-automotive EV markets are quickly adopting superior battery applied sciences. Every sector presents distinctive calls for and alternatives for development.

- The Warehouse Revolution: The warehouse sector, which incorporates electrical forklifts, personnel carriers and inventory chasers, is quickly shifting from nickel batteries and propane powertrains to lithium-ion battery powertrains. Lithium-ion battery expertise has enabled better adoption of electrical energy versus propane or pure fuel however can be driving a change from nickel batteries to Li-ion. The marketplace for electrical warehouse gear is projected to expertise substantial development as a consequence of rising demand from the e-commerce trade, a rising concentrate on sustainability and developments in battery expertise.

- Reworking Transportation: Vans and Buses: Electrical vehicles and buses are gaining momentum, spurred by technological improvements and stringent emission laws. The anticipated value parity with diesel vehicles and buses accelerates their adoption, additional supported by battery developments promising enhanced efficiency and decreased environmental affect.

- Building Trade Electrification: Electrification in building gear is gaining traction, with electrical equipment requiring batteries that face up to harsh environments. The heavy-duty electrical automobile battery market, together with these utilized in building functions, is adapting to those wants with ruggedized battery designs and is predicted to expertise important development, with forecasts indicating a Compound Annual Development Charge (CAGR) between 10% and 15% over the subsequent decade. This development is pushed by growing environmental laws, rising gas prices and developments in battery expertise that may higher swimsuit demanding building wants. A documented profit additionally exists from decreased air pollution and employee hazards in poorly ventilated building environments. Furthermore, inner-city noise-related ordinances regulate the working hours of loud diesel building gear, however these restrictions could not apply to quieter electrical alternate options.

- The Rise of Electrical Bikes: Globally, the electrical motorbike market is experiencing exponential development, with projections indicating an growth from a $30 billion market to over $140 billion by 2030. This surge is basically fueled by lithium-ion batteries, whose light-weight design and excessive vitality density meet the particular calls for of this sector.

- Marine and Aerospace Improvements: Marine and aerospace industries are tapping into superior battery applied sciences, with market projections indicating important development. These sectors concentrate on growing batteries that handle challenges like corrosion resistance and weight constraints, typically involving hybrid techniques and renewable vitality options. The worldwide marine battery market alone is anticipated to increase from $1.3 billion in 2024 to $5.4 billion by 2032.

Challenges and Options in Non-Automotive EV Battery Growth

Within the realm of non-automotive electrical automobiles (EVs), industrial batteries encounter distinct challenges which are essential to their efficiency and security. For one, efficient thermal administration is paramount to forestall overheating and guarantee reliability throughout charging and discharging cycles. Moreover, attaining weight discount with out compromising battery efficiency is important for enhancing automobile effectivity.

The necessity for sturdy sealing options is equally essential, because it protects battery enclosures from environmental elements and maintains operational integrity. Moreover, enhancing the sturdiness and longevity of those batteries is significant to face up to the rigorous calls for and situations they face. Addressing these challenges is prime to advancing the capabilities and security of business batteries in non-automotive EV functions.

Parker leverages its experience in superior supplies and applied sciences to sort out the formidable challenges confronted by battery producers within the non-automotive EV sector. By implementing cutting-edge thermal administration options, optimum warmth dissipation is achieved, safeguarding towards overheating and enhancing total battery reliability.

Moreover, encapsulants and potting compounds, together with the CoolTherm portfolio, are designed to enhance the sturdiness and longevity of battery packs by offering sturdy safety and thermal administration. Parker tailors these options to fulfill the particular wants of non-automotive EV functions, guaranteeing optimum battery efficiency and decreased downtime.

Capturing Alternatives in a Dynamic Market

The demand for superior battery applied sciences is ready to develop as industries proceed to innovate. The economic battery market displays a broader dedication to sustainability and operational effectivity, with sectors like building, transportation and logistics main the cost. As these industries proceed to innovate, so will Parker. With tailor-made options, Parker continues to not solely meet however exceed the particular wants of every sector. Parker invitations you to discover how their superior applied sciences for batteries can empower your operations and drive success in these dynamic markets.

Integrating thermally conductive adhesives, resembling Parker’s CoolTherm TC-2002, into battery techniques underscores the strides being made to boost efficiency and security. By managing thermal hundreds successfully, these adhesives prolong battery lifespan, enhance security and guarantee constant efficiency even in difficult environments.

For companies aiming to capitalize on these market alternatives, understanding the evolving panorama and the position of superior battery expertise is essential. Parker’s options supply a pathway to success, empowering operations throughout numerous sectors with tailor-made applied sciences that meet particular trade wants.

The electrification of business automobiles and the rise of non-automotive EV markets sign a brand new period in battery expertise. By addressing key challenges in thermal administration and sturdiness, and exploring rising markets, industries can leverage these developments to drive development and innovation.

For extra insights into how Parker’s superior applied sciences can revolutionize your industrial battery techniques, go to their web site or attain out to their group to discover the most recent in thermally conductive adhesives and different cutting-edge options.