Because the world races in direction of a future powered by sustainable vitality options, electrical automobiles (EVs) have emerged as a pivotal expertise in decreasing carbon emissions and reliance on fossil fuels. Central to the viability and security of EVs are their battery techniques, which demand meticulous inspection and high quality management. LMI Applied sciences, a world chief in 3D scanning and inspection options, is working to advance EV battery inspection with cutting-edge sensible 3D applied sciences geared toward enhancing manufacturing effectivity, accuracy, and security requirements.

The Rising Want for 100% Inspection of EV Batteries

The significance of strong battery inspection options can’t be overstated within the realm of electrical automobiles. EV batteries are intricate assemblies of quite a few cells and modules, every essential to the car’s efficiency and longevity. The subtlest defects or inconsistencies can result in compromised effectivity, decreased vary, and even security hazards reminiscent of overheating or malfunctioning. Furthermore, as the dimensions of EV manufacturing ramps up globally, guaranteeing constant high quality management turns into more and more difficult but completely important.

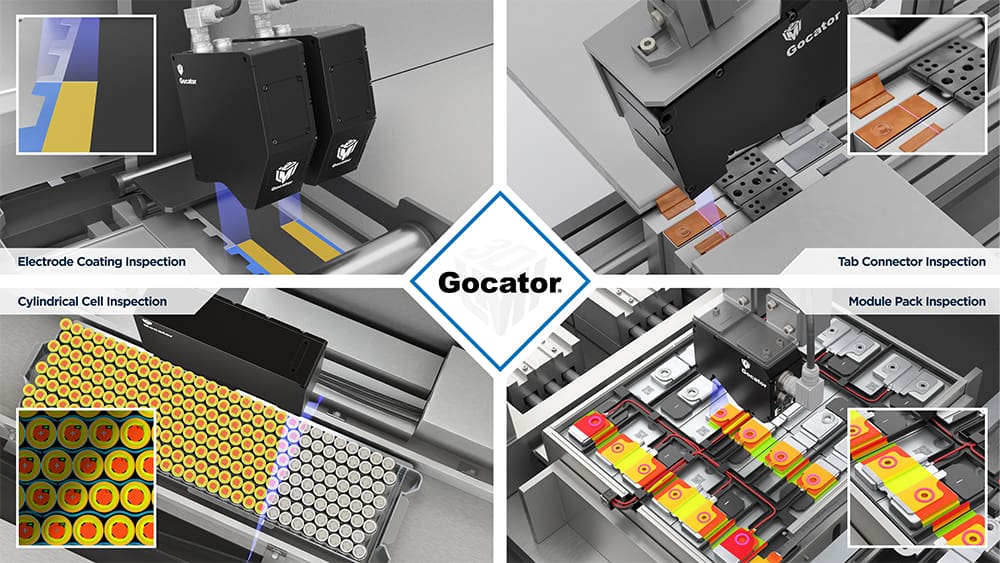

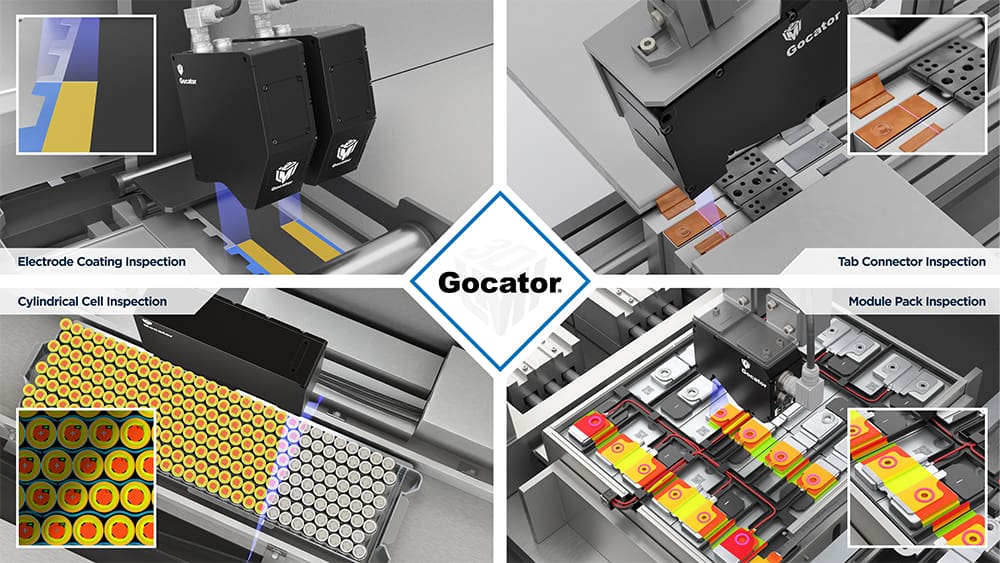

Good 3D Scanning and Inspection for Automated High quality Management

LMI Applied sciences is a trusted supplier of 3D scanning and inspection techniques on this house, providing complete options that cater particularly to the wants of EV battery producers. With a powerful emphasis on precision and reliability, the corporate’s options play an instrumental function in streamlining manufacturing processes and enhancing the general high quality of EV battery manufacturing at scale.

The Core Applied sciences Driving The Good 3D Answer Method

On the coronary heart of LMI Applied sciences’ EV battery inspection options lies a seamless mixture of superior {hardware} and complex software program.

Excessive-Pace, Excessive-Decision 2D/3D Scanning

The Gocator sensor product line is famend for its high-resolution 2D/3D scanning capabilities and types the spine of LMI’s inspection techniques. These sensors embody laser, snapshot, and line confocal applied sciences that seize detailed 2D depth (distinction knowledge) and 3D floor (peak knowledge) profiles and dimensions of every battery cell with the very best diploma of accuracy. This functionality not solely ensures exact measurement of cell dimensions but in addition permits the detection of small defects reminiscent of floor swelling, warping, weld fractures, and errors in electrode placement. These sensors even have specialised options, reminiscent of Gocator 2600’s HDR mode, that allows excellent efficiency in difficult EV inspection purposes.

The Gocator 2500 Sequence is a well-liked selection for EV battery inspection on account of its high-speeds and glorious efficiency on highly-reflective machined-metal battery surfaces.

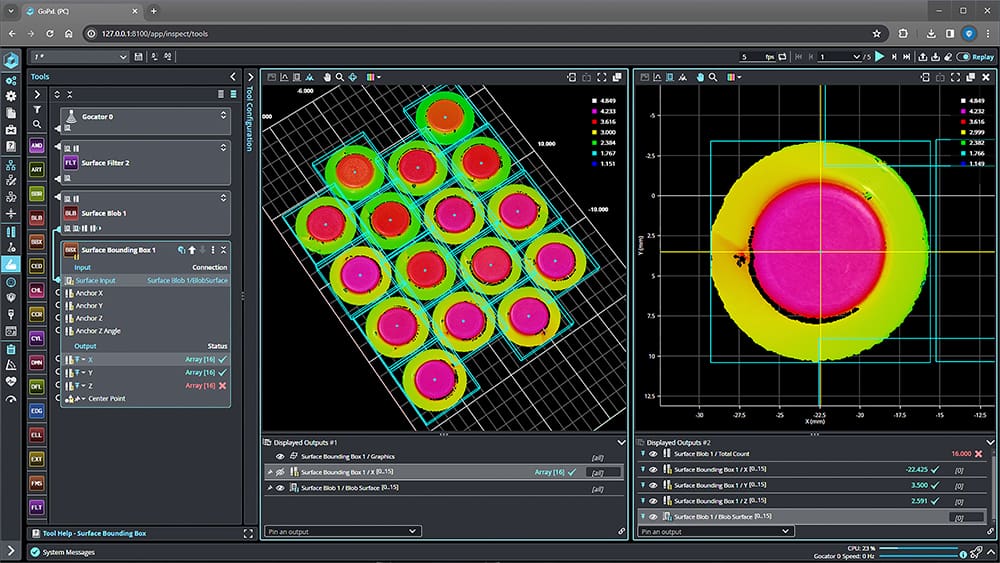

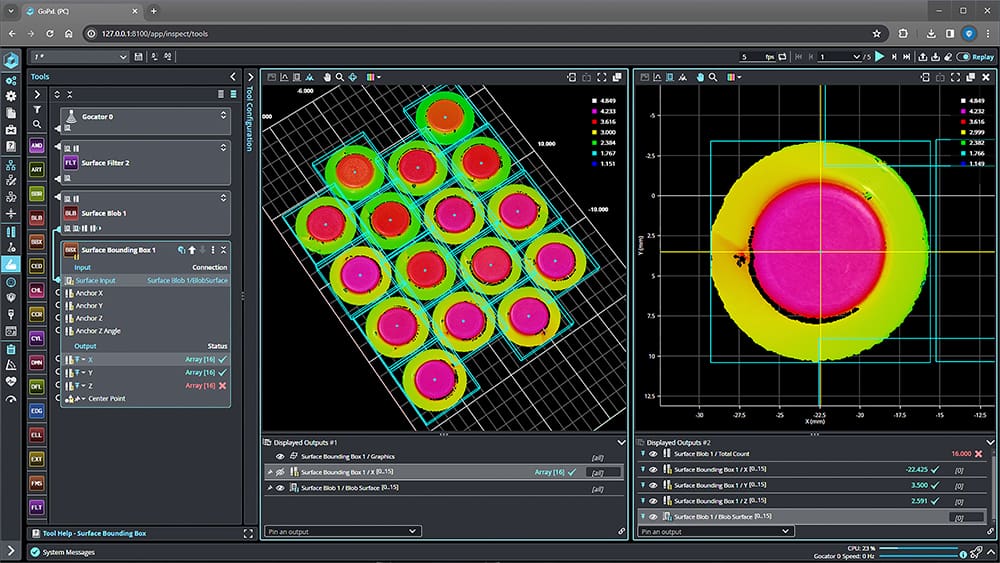

Embedded Good 3D Inspection Software program

Complementing the {hardware} is GoPxL, LMI’s newest iteration of its proprietary sensible 3D inspection software program. Not like many competing options that require the consumer to run separate third celebration software program on an exterior machine, GoPxL runs on-sensor and is accessed via an intuitive and easy-to-use internet browser interface. This sensible software program offers customers with direct entry to superior measurement algorithms to research scanned knowledge, guaranteeing EV batteries are manufactured inside tight geometric tolerances and figuring out potential defects that will point out high quality points. By automating the inspection course of, LMI helps producers keep consistency in high quality throughout large-scale manufacturing runs, minimizing the influence of human error and enhancing total operational effectivity.

Integration and Customization

Recognizing the various wants of EV battery producers, LMI Applied sciences presents versatile integration choices and customization capabilities. Whether or not it’s integrating with present manufacturing strains or tailoring inspection parameters to particular battery designs, LMI works carefully with producers to make sure seamless deployment and optimum efficiency of their inspection options.

Benefits for EV Producers

The adoption of LMI Applied sciences’ EV battery inspection options presents a number of distinct benefits for producers:

- Enhanced High quality Management: By detecting defects early within the manufacturing course of, producers can forestall defective batteries from getting into the market, thereby safeguarding shopper belief and model status.

- Elevated Effectivity: Automated inspection reduces the time and labor required for high quality management, permitting producers to scale manufacturing with out compromising on high quality requirements.

- Compliance and Security: Assembly stringent regulatory requirements for EV batteries is non-negotiable. LMI’s inspection options assist producers adjust to security laws and business requirements, guaranteeing that each battery meets or exceeds required specs.

Trade Influence and Future Prospects

The influence of LMI Applied sciences’ improvements extends past particular person producers to the broader EV business. As EV adoption continues to surge globally, the demand for dependable, scalable battery inspection options will solely intensify. LMI’s dedication to ongoing analysis and improvement ensures that its applied sciences evolve in tandem with business wants, staying forward of rising challenges reminiscent of elevated battery capacities, new cell chemistries, and evolving regulatory landscapes.

Wanting forward, LMI Applied sciences stays poised to play a pivotal function in shaping the way forward for EV battery inspection. By leveraging developments in AI-driven analytics, machine studying, and robotics, LMI goals to additional improve the velocity, accuracy, and flexibility of its inspection options. This continuous innovation not solely reinforces LMI’s place as a pacesetter in 3D inspection but in addition underscores its dedication to supporting the transition in direction of a sustainable automotive ecosystem.

Driving In the direction of a Sustainable Future

LMI Applied sciences’ dedication to excellence in EV battery inspection represents a cornerstone of the electrical car revolution. By empowering producers with state-of-the-art 3D scanning and inspection capabilities, LMI not solely enhances operational effectivity and product high quality but in addition contributes to the broader targets of sustainability and security throughout the automotive business. As the worldwide panorama continues to evolve, LMI Applied sciences stands able to companion with producers, driving innovation and setting new benchmarks in EV battery inspection options.

In a world the place each innovation counts in direction of a greener future, LMI Applied sciences stands out as a beacon of progress, remodeling challenges into alternatives and paving the way in which for a sustainable tomorrow powered by electrical automobiles.

LMI Applied sciences is a trusted world supplier of sensible 3D scanning techniques for 100% EV battery inspection, providing complete options that cater particularly to the wants of producers. With a powerful emphasis on precision, reliability, customization, and buyer help, the corporate’s options play an instrumental function in streamlining manufacturing processes and enhancing the general high quality of EV battery manufacturing at scale.