Large Machines Take Completely different Paths to EV

Many present electrical automobile (EV) efforts concentrate on passenger automobiles. Whereas these are the most important contributors to transportation-related emissions, sustainability initiatives also needs to make room for heavy industrial tools.

Building equipment and different off-road autos account for 10% of all transportation greenhouse fuel emissions—double the rail and maritime sectors mixed. Fortunately, electrical options to traditional machines have began to return into the market. This shift stems from just a few key technological enhancements.

Subsequent-Technology Batteries

Like in client autos, battery-electric options are essentially the most outstanding electrification resolution in heavy tools. Nonetheless, standard EV batteries wrestle to fulfill industrial machines’ want for lengthy working hours in harsh working circumstances.

Modular batteries provide just a few key enhancements. These parts are interchangeable between machines of all sizes, permitting groups to swap modules between autos as an alternative of stopping work to recharge. This setup additionally means spare batteries can cost off-site to protect their high quality earlier than they’re wanted on the job.

Cells with increased energy densities, higher working temperature ranges and sooner cost instances additionally make electrification more and more viable. Drops in costs likewise make EVs a greater different for budget-constrained initiatives.

Hydrogen Gas Cells

Hydrogen energy is one other rising resolution. Gas cells are perfect for heavy equipment that may’t sit idle for lengthy intervals to recharge, as refueling takes just a few minutes. Hydrogen can be the world’s most energy-dense gas (for its mass), permitting tools to run longer between fueling stops.

Traditionally, gas cells have been too costly to implement in most functions, however that’s altering as analysis makes them cheaper and extra environment friendly. The worldwide power sector has already decreased its emissions by 30% because of broader hydrogen energy adoption.

Heavy equipment—which companies usually lease and desires further energy—can be a greater match for hydrogen than street autos. Consequently, it might come to industrial use circumstances earlier than business automobiles.

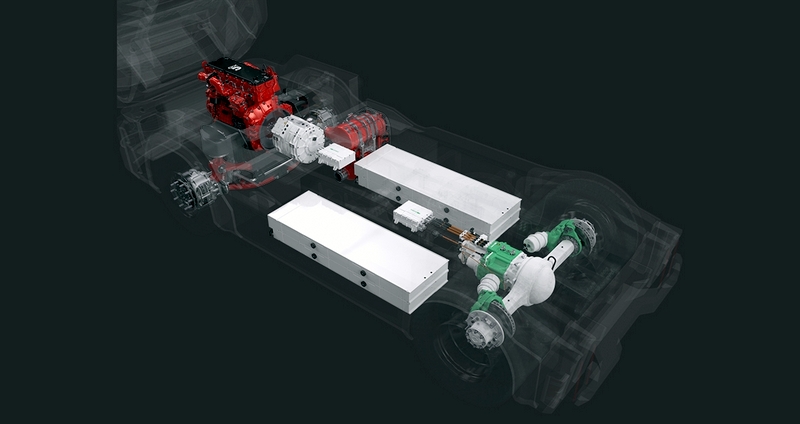

Hybrid Gear

Hybrids are price contemplating, too. Whereas combining combustion engines and electrical motors does nonetheless entail some emissions, it lets firms cut back their carbon footprint with out as a lot funding or as vital a change in workflow. Consequently, the know-how is a useful stepping stone to a completely electrical future.

Companies acknowledge this chance, too. Hybrids are the fastest-growing electrical building tools phase, seemingly because of a mix of their familiarity and the truth that many producers make them. Decreasing emissions by means of these machines might assist heavy industries transfer nearer to environmental objectives earlier than enhancements in batteries and gas cells make these choices extra commercially viable.

Challenges Stay in Gear Electrification

Improvements in batteries, gas cells and hybrids are making the dream of efficient electrical tools a actuality. Nonetheless, the sector hasn’t overcome all of its challenges but. Whereas prices will be the largest impediment in client functions, accessibility is a bigger concern for industrial-grade equipment.

The dearth of charging infrastructure close to worksites makes it tough to justify a fleet of electrical machines. It takes as much as eight hours to completely recharge the massive EV batteries utilized in heavy tools (with 240V Stage 2 charging), and a few heavy tools cells could require much more time. Time can be a luxurious most building initiatives don’t have. Sooner-charging batteries or moveable quick chargers could also be obligatory to beat this barrier.

Hydrogen provides a possible resolution, however hydrogen gas is even much less broadly out there. Comparatively few producers produce gas cell-powered tools, too. The market might want to mature earlier than firms could make vital modifications to their fleets.

The Way forward for Heavy Gear Is Electrical

Regardless of such challenges, electrical heavy tools has made spectacular strides. Additional analysis, development and market progress will ultimately pave the way in which for low-emissions industrial work. When that shift will happen remains to be unsure, however organizations have already got choices to cut back their carbon footprints whereas sustaining productiveness.

The put up Exploring the Tech Making Heavy Gear Electrification Attainable first appeared on Clear Fleet Report.