The off-highway equipment sector is quickly adopting electrification resulting from regulatory pressures and the demand for sustainability. Though slower than different sectors, this transition provides a singular alternative to implement confirmed applied sciences.

A generational strategy to electrification

The evolution of electrification in different sectors supplies a roadmap for the off-highway {industry}. Early electrical forklifts and indoor equipment paved the best way for contemporary passenger EVs, proving emissions-free options in demanding environments. This sample is now repeating, with off-highway electrification benefiting from mature electrical applied sciences developed in different sectors.

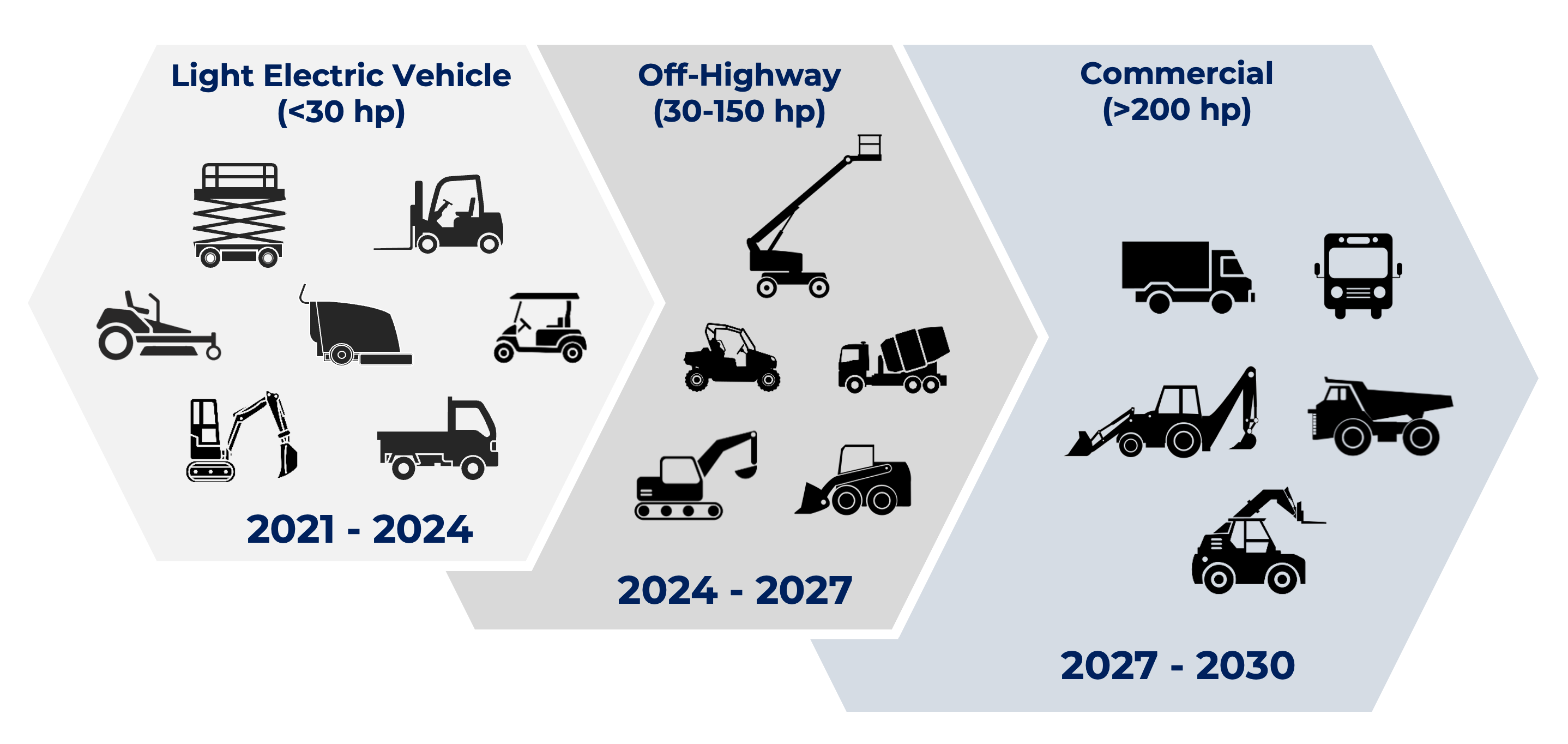

A 3-part “generational mannequin” for electrification might be noticed:

- Era 1: Preliminary designs utilizing normal components from different industries to create an electrical drivetrain.

- Era 1.5: An iterative section refining designs to boost efficiency, scale back prices, and delegate extra duties to suppliers.

- Era 2: Full maturity, the place third-party integrators handle optimized subsystems, permitting OEMs to concentrate on market-specific customization and seamless integration.

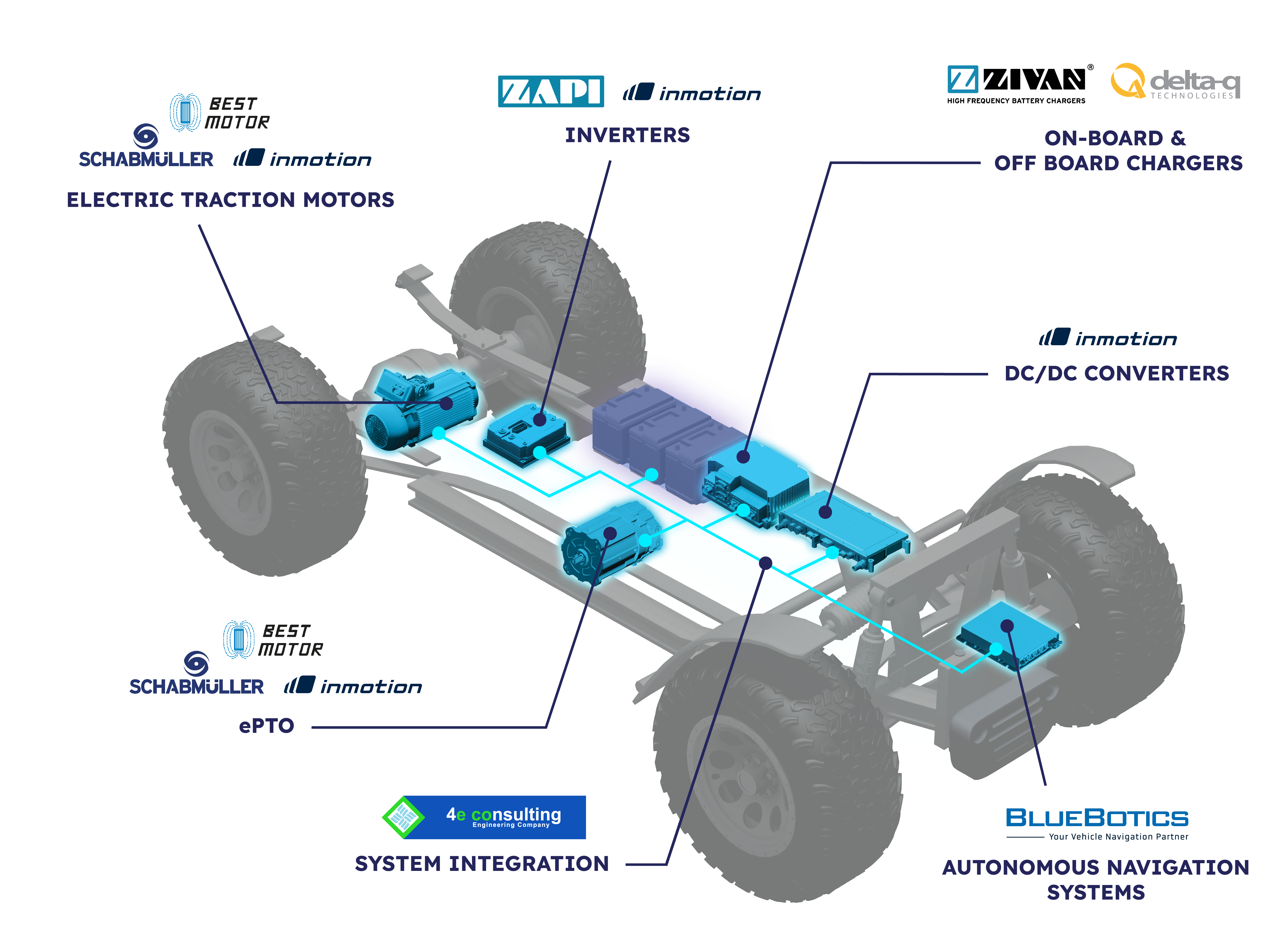

The final word purpose is totally built-in drivetrains, the place every part works in concord for max effectivity.

The important position of charging options

Choosing the proper charging answer is essential for attaining an built-in future for electrified equipment. A charger tailor-made to the particular machine software will enhance battery effectivity, security, and lifespan. On condition that the battery is often the costliest part, defending and maximizing its worth by way of the proper charger is important.

On-board charging options bridge the hole between a machine’s battery and various charging infrastructures. Nonetheless, it’s essential to think about each on-board and off-board charging options, sizing the charger primarily based on out there connections, battery cost charges, and the working atmosphere.

Electrification traits and market elements

Autos are main contributors to greenhouse fuel emissions, making electrification a key answer. The transition to electrical automobiles (EVs) is going on throughout numerous sectors, together with industrial, off-highway, and automotive.

The off-highway sector is projected to see elevated adoption of electrification from 2024-2027. A useful case research might be discovered within the materials dealing with sector, the place electrical forklift gross sales have surged by 140%, in comparison with solely a 14% enhance in inner combustion (IC) forklifts.

This progress is pushed by a number of elements:

- Decrease working prices

- Decreased upkeep

- Elevated productiveness

- Enhanced operator consolation

- Rules just like the CARB IC forklift ban

Whereas larger upfront prices and charging infrastructure stay hurdles, the market is clearly shifting in the direction of electrical options.

Rising applied sciences and real-world softwares

A number of applied sciences are remodeling electrification:

- Gallium Nitride (GaN) and Silicon Carbide (SiC) are enhancing energy electronics by minimizing losses and boosting efficiency.

- Lithium batteries supply larger power density and integration capabilities for industrial equipment.

- Battery administration techniques (BMS) enhance security, present upkeep insights, and optimize charging profiles.

- CAN bus protocols allow distant fleet monitoring and administration, streamlining operations and lowering downtime.

Overcoming challenges by way of integration and collaboration

Built-in electrical drivetrains differ from inner combustion engines, the place every part enhances the efficiency of the others. This interconnectedness requires OEMs to stability flexibility and value effectivity.

- Non-integrated setups: Supply flexibility however incur larger upfront prices.

- Totally built-in options: Are cost-optimized however lack flexibility for impartial upgrades.

The hot button is strategic collaboration with electrification specialists. By leveraging cross-industry insights and provide networks, OEMs can develop tailor-made electrified options. Partaking suppliers early within the design course of ensures manufacturable specs and real looking efficiency expectations.

ZAPI Group are system integration specialists and have a extremely built-in product portfolio, together with:

- Movement controllers

- Electrical motors

- Excessive-frequency battery chargers

- Autonomous navigation software program for full-electric and hybrid purposes

Electrification: A necessity for the off-highway equipment sector

Electrification is now not non-compulsory for the off-highway equipment sector; it’s a regulatory and operational necessity. Because the {industry} strikes towards totally built-in options, early collaboration with electrification specialists is crucial for a seamless transition to an all-electric future.

Electrification is not only about powering equipment; it’s about powering progress. OEMs that embrace these applied sciences with the proper companions will cleared the path. The off-highway sector can leverage the progress made in established ecosystems just like the Materials Dealing with {industry}.

The fourth digital Way forward for Electrification convention, going down 26-27 February, 2025, will discover these themes and extra. Registration is free and open to all iVT Worldwide readers.